Your Cart is Empty

Free UK delivery over £50 | Expert Knowledge & Advice | UK Customer Support | 30 Day Returns Guarantee

As we discussed in our article about earpads, weight and clamping force, to get the amazing bass that’s one of the hallmarks of planar magnetic headphones, the seal between the earpads and head is crucial. Most earpads typically use die cut or molded foam covered with leather or synthetic material, and they tend to be completely flat and/or angled slightly so they’re thicker in the back.

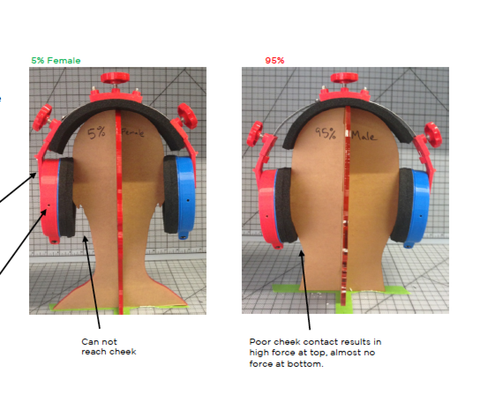

The area of the head behind the pinna is not flat, which makes designing thin flat earpads that offer a good seal quite a challenge. Years ago, we envisioned an earpad material that could be molded into a specific shape, which would be contoured to be thicker behind the ear and gradually narrow toward the front in a convex way, to more closely match the shape of most human heads.

For our first attempt, we worked with an ear-tip foam manufacturer to see if we could simply mold the foam into the 3D shape we were picturing. They had just created a new material for their in-ear foam tips that would also form a skin over the foam during the molding process. We made several samples and the initial results were promising.

The early prototypes for the EL-8 headphone were hand built for their unveiling at a trade show. The new earpads didn’t look as impressive as leather pads, but the fit was amazing. The new foam material was super soft and the skin on the foam offered protection so you could clean it with water.

We started doing environmental testing on the new headphones and the wheels fell off: the new pads deterioratedvery quickly. We had to make a decision with the product launch coming soon, so we abandoned the idea temporarily and switched to our “protein leather” backup, which is made with egg protein and feels a lot like real leather, but was more of the traditional flat/angled shape.

When we started designing the Mobius headphone in late 2017, we decided to revisit the earpad design and see if we could make the contoured shape we had envisioned years earlier. We visited many earpad factories, but couldn’t figure out the best way to manufacture them. One of our packaging vendors (Mike) was visiting Audeze one day and we were testing prototype Mobius units. We showed him the issues with the earpads and what we wanted from the seal.

Mike started a small packaging company in the 1970s that he grew into a 3PL here in Santa Ana. He had been in the field for more than 40 years and he knew most of the companies in Orange County. Mike told us that he might be able to help, and the next day we went to a small factory behind Angel Stadium in Anaheim. We met with the owner who agreed to show us his foam molding process. Upon entering a brightly lit factory floor we immediately noticed massive rolls of flat foam. The rolls were being sliced into smaller rectangular shapes before being molded into an invitingly curvy product. We looked closer at what they were making, and lo and behold… it was push-up bras. The foam pieces were being fed into a thermoforming machine that made bras for various brands. The owner explained that when they make the molds, they can carve out patterns that imprint flowers and brand names on the foam-- it was very precise and exactly the process we needed. Here’s a sample they let us take with us:

And that’s how we figured out the process of making contoured ear-pads that fit better, are more comfortable and provide a great seal. We’ve since found a way to make a similar contoured shape with a gel interior for an even better seal and a pleasant cooling effect. Just one of the ways Audeze is always tirelessly researching to bring you uncompromised audio.